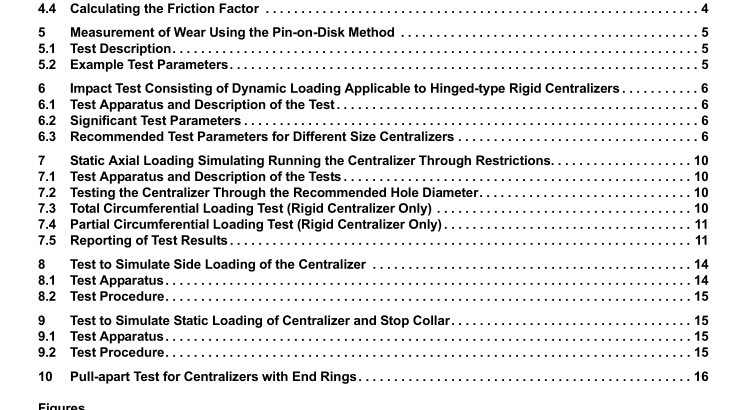

API TR 10TR5:2008 pdf free download.Methods for Testing of Solid and Rigid Centralizers

7 Static Axial Loading Simulating Running the Centralizer Through Restrictions

7.1 Test Apparatus and Description of the Tests Although operators plan to drill wellbores to gauge dimensions, there are many factors and circumstances, such as use of bi-center bits, worn bits, and swelling formations that can lead to running casing and casing hardware (centralizers, stop collars, etc.) through tortuous wellbores, under gauge hole sections, ledges, and keyseats. Testing is recommended to determine the effects of running centralizers through these restrictions.

7.1.1 Test Instrumentation The instrumentation should be capable of accurately recording or otherwise indicating the application of vertical loads, including the maximum load applied during the test, as well as the load at initiation of possible damage and/or failure of the centralizer, and if the safe limit of the testing device is reached (maximum allowed load level).

7.2 Testing the Centralizer Through the Recommended Hole Diameter In this test the centralizer is run through the recommended (design) wellbore diameter to verify that the OD of the entire centralizer is as specified by the manufacturer. The test assembly (see Figure 7) consists of an inner test casing (push mandrel) with an attached centralizer and a restriction sleeve (standard hole). The inner test casing should be similar to the inner test casing used to perform a starting or running force test as required by API Spec 1 0D (ISO 1 0427-1 ). The inner test casing for the restriction tests described in this section must be sufficiently robust to withstand expected loads. The restriction sleeve should be within the tolerances indicated in ISO 1 1 960 for non-upset pipe. Burrs or similar defects should be removed prior to testing.

The restriction sleeve should provide a circular restriction through which the centralizer may pass. The upper edge of the restriction should have a 45-degree, beveled end. The restriction sleeve should also be of sufficient length to allow passage of the entire length of the centralizer through the restriction. The restriction sleeve should rest, vertically or horizontally, against a fixed surface. The centralizer should be installed on the inner test casing per manufacturer’s recommendations. One possible installation is one end of the centralizer mounted flush with one end of the inner casing. Another installation uses a stop device between the end collars. This end is inserted in the restriction sleeve.

The restriction sleeve should be axially aligned with the centralizer to contact the centralizer. An axial load shall be applied to the top of the inner test casing to force the centralizer against or through the restriction sleeve while recording the load applied. Suggested load rate should be 500 lbf to 1 ,000 lbf per second. The test should be continued until the centralizer fails, is completely inside the restriction, or a maximum load of 50,000 lbf has been applied.

7.3 Total Circumferential Loading Test (Rigid Centralizer Only) This test simulates the effect of running rigid centralizers through an under gauge hole section. The centralizer is pushed through a circular restriction smaller than the OD of the centralizer. The test assembly (Figure 8) consists of an inner test casing (push mandrel) with an attached centralizer and a restriction sleeve configured as follows:

• an upper section with a diameter of the standard hole;

• a transition with a 45-degree bevel into the lower section;

• a lower with a recommended restriction diameter which is 0.50-in. smaller than the maximum OD of the centralizer full bore restriction diameter. The inner test casing should be similar to the inner test casing used to perform a starting or running force test as required by API Spec 1 0D (ISO 1 0427-1 ). API TR 10TR5 pdf download.API TR 10TR5:2008 pdf free download