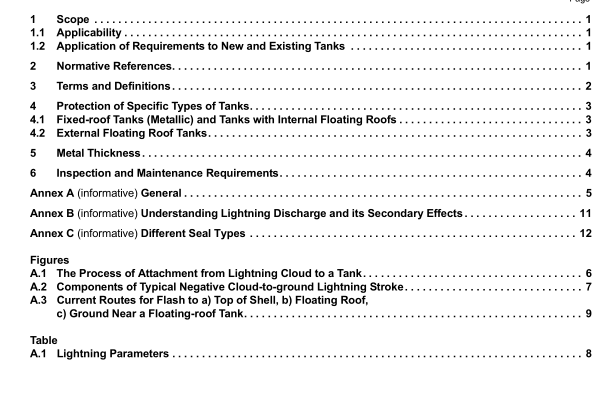

API RP 545:2009 pdf free download.Recommended Practice for Lightning Protection of Aboveground Storage Tanks for Flammable or Combustible Liquids

4 Protection of Specific Types of Tanks

4.1 Fixed-roof Tanks (Metallic) and Tanks with Internal Floating Roofs For fixed roof tanks (metallic cone or dome) and internal floating-roof tanks (IFRTs), there is a possibility of flammable vapors being present at atmospheric vents. If present, flammable vapors can be ignited by a lightning flash. Shunts or bypass conductors are not required for lightning protection. Bonding techniques to prevent static discharge between the floating roof and shell are addressed in API 650, Appendix H. Tanks handling low vapor pressures or in-service with properly maintained floating roofs with tight-fitting seals are not likely to have flammable vapors at atmospheric vents unless it is being refilled from empty. In these cases, no further lightning protection is required (see Annex B).

4.2 External Floating Roof Tanks

4.2.1 Bonding Between Floating Roof and Shell 4.2.1.1 Shunts for Conduction 4.2.1.1.1 General Shunts are used for conduction of fast and intermediate duration components of lightning-stroke current.

4.2.1.1.2 Number and Placement The shunt to shell contact point shall be submerged at least 0.3 m (1 ft) below the surface of the liquid product. The shunt shall have as short and direct a path as possible from the conductive floating roof to the tank shell. The shunts shall be spaced at intervals no greater than 3 m (10 ft) around the perimeter of the floating roof. When retrofitting existing tanks with submerged shunts, the abovedeck shunts shall be removed. 4.2.1.1.3 Cross-sectional Area—Minimum Width and Material The shunts shall consist of an austenitic stainless steel conductor of at least 20 mm 2 (0.031 in. 2 ) cross-sectional area, or of other material conductors of equivalent current-carrying capacity and corrosion resistance. The minimum width of the shunt shall be 51 mm (2 in.). The shunts shall be of the minimum length necessary to permit the function of the floating-roof seal assembly. The shunts shall be of the minimum length necessary to remain in contact with the shell during the full horizontal and vertical design movement of the floating roof.

4.2.1.1.4 Durability The shunts and termination connections shall be of sufficient flexibility, cross-sectional area, and corrosion resistance to have a minimum service life of 30 years.

4.2.1.2 Bypass Conductors

4.2.1.2.1 General Bypass conductors are used for conduction of the intermediate and long duration component of lightning-stroke current.

4.2.1.2.2 Number, Length and Electrical Resistance The tank floating roof shall be bonded to the tank shell by direct electrical connection through an appropriate number of bypass conductors. Each conductor, including connections, shall have a maximum end-to-end electrical resistance of 0.03 Ω. The bypass conductors shall be of the minimum length necessary to permit full movement of the floating roof. Bypass conductors should be evenly spaced not more than every 30 m (100 ft) around the tank circumference with a minimum of two.

4.2.1.2.3 Durability The bypass conductors and termination connections shall be positioned and of sufficient flexibility, cross-sectional area, and corrosion resistance to have a minimum service life of 30 years.

4.2.2 Parallel Conducting Paths (Seal Assembly from the Floating-roof Tank) Any non-fully submerged conductive seal assembly components including springs, scissor assemblies, seal membranes, etc. shall be electrically insulated from the tank roof. The insulation level shall be rated 1 kV or greater. NOTE This allows any lightning discharge current from the floating roof to the tank shell to take the preferential path through the shunts and bypass conductors.

4.2.3 Insulation of Gauge or Guide Poles Any gauge or guide pole components or assemblies that penetrate the tank floating roof shall be electrically insulated from the tank floating roof. The insulation level shall be rated 1 kV or greater.API RP 545 pdf download.API RP 545:2009 pdf free download