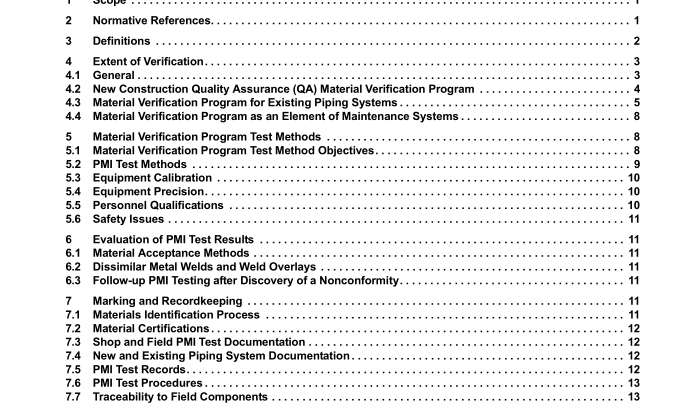

API RP 578:2010 pdf free download.Material Verification Program for New and Existing Alloy Piping Systems

4.2.6 PMI Testing of Welding Consumables When welding is conducted, one electrode or wire sample from each lot or package of alloy weld rod should be positively identified. The remainder of the lot should be compared to the sample to verify that the markings of the wires/electrodes are correct. Some weld rods have the alloying elements contained in the flux, and do not meet the alloy specification until welded. PMI testing of weld metal (e.g. deposited weld metal or undiluted weld “buttons”) is a permissible alternative to PMI testing of an electrode or wire sample provided it is conducted immediately prior to welding or during the welding process.

4.2.6.1 Longitudinal Pipe and Fitting Welds Where there is reason to suspect problems, longitudinally welded alloy pipe and fittings should receive random PMI testing verification of the base metal and weld metal.

4.2.6.2 Autogenous Welds If the owner/user determines that material verification testing is required on autogenous-welded (with no added filler metal) alloy pipe or fittings, it is necessary to conduct testing on only the base metal.

4.2.7 PMI Testing of Components Supplied by a Distributor A higher degree of PMI testing verification should be conducted on alloy material supplied by stocking distributors due to the potential for material mix-ups as a result of handling.

4.3 Material Verification Program for Existing Piping Systems 4.3.1 General This section covers alloy piping systems that are already in service where the material verification program procedures for the construction were not in accordance with 4.2. Material verification is limited to the pressure- containing components and their attachment welds. It is important to recognize that previous maintenance activities, as well as new construction practices, may influence the likelihood of inadvertent materials substitutions.

4.3.2 Responsibilities The owner/user is responsible for determining if a retroactive material verification program is appropriate for each existing piping system, for prioritizing the piping systems to receive retroactive PMI testing, and for determining the extent of PMI testing required.

4.3.3Prioritizing Piping systems for Retroactive PMl Testing

lf the owner/luser elects to prioritize piping systems for the material verification program or needs to determinewhether PMl testing is needed at all, the ownerluser should consider the following.

a) Likelihood of a material mix-up during previous project and maintenance activities.A key factor is the

effectiveness of the material verification program at the time of these activities.

b)Consequences of a failture. Some factors to be considered include flammability, fire potential, toxicity, proximity to

other equipment or community, temperature, pressure, mode of failure, and size of release.

c) Reason for alloy specification (i.e.corrosion resistance or product purity).

d) Historical data relating to inadvertent material substitutions. This may be related to previous experience with

material nonconformities in the process unit or within the operating plant.

Taken together, these factors can be used to determine the risk associated with possible material nonconformancesin a piping system. The ownerluser should establish a methodology for estimating the relative priority for PMl testingof various piping circuits within a given unit.This methodology may be based on qualitative or quantitative riskanalysis.API 581 discusses several risk-based approaches and the factors that should be considered whenconducting a risk analysis such as material, service conditions, service fluid, and mode of failure.

4.3.3.1 Carbon Steel Substitutions in Low Alloy Steel Systems

In determining the likelihood of material nonconformances, it is worth noting that historically the greatest number ofmaterial nonconformances with serious consequences have involved carbon steel components in low alloy steel(e.g.11/4 Cr-12 Mo,2’14 Cr-1 Mo, 5 Cr-12Mo, 9 Cr-1 Mo) piping systems. There have been fewer nonconformancesin stainless steel and nonferrous (e.g.Monel, Inconel) systems because of appearance and weldability issues.

4.3.3.2 Residual Elements In Carbon Steels In Hydrofluoric Acid Alkylation Units

Carbon steels in some specific locations in HF acid service have been reported to suffer increased corrosion ratesbased on the residual elements (RE)(i.e.C, Ni, Cr, and Cu) in the steels, and is discussed in APl751.PMl methodscan be used to assess the potential for enhanced corrosion in HF service. Consideration should be given to the abilityof the PMl method to detect the various elemental concentrations.

4.3.3.3Gasket Materials

Incorrect gasket materials in incompatible service may cause premature failings. The main principles outlined in thisdocument can be applied to gasket materials. The ownerluser is required to ascertain the potential material variationsand select analytical methods capable of providing the required data. The actual test procedures can be moredetailed due to the geometric structure of the gasket materials.API RP 578 pdf download.API RP 578:2010 pdf free download