API TR 6AF3:2020 pdf free download.High-pressure High-temperature (HPHT) Flange Design Methodology

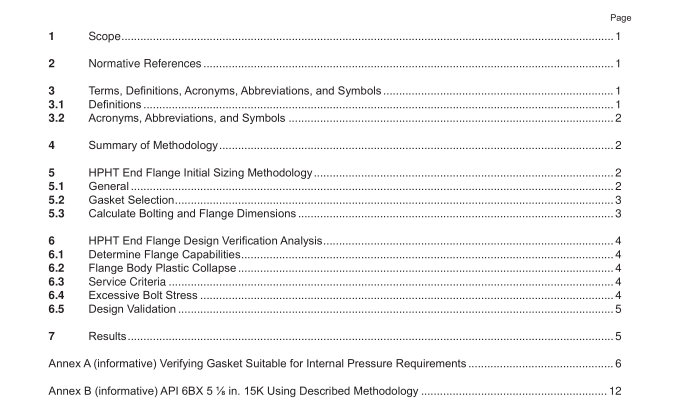

4 Summary of Methodology

The methodology is comprised of four distinct phases:

1 ) Select a gasket for the internal pressure requirements

2) Calculate the bolting and fange dimensions

3) Determine the fange’s capabilities with regards to pressure, bending and tension loading

4) Validate the fange design in accordance with an industry accepted specifcation.

Loading conditions addressed by this guideline are pressure and bending. Loading conditions not addressed by this guideline include torsion, transverse shear, thermal gradients, and tension.

Failure modes addressed by this guideline are fange body plastic collapse, fange body excessive deformation, and bolt failure under monotonic (as opposed to cyclic) loading conditions.

Failure modes not verifed by the guideline include leakage, local strain and fatigue. According to PN 90-21, API 6BX fanges (or bolting) will likely be overstressed before 6BX gasket leakage. For this reason, this document does not assess the 6BX gaskets for leakage. This is based on 6BX gaskets maintaining critical sealing contact stress after hub-separation. It assumes that pressure is applied prior to external loading. These fndings were supported by validation testing on 4 1 / 1 6 and 7 1 / 1 6 6BX fanges. Application where fanges are subjected to external loading prior to pressurization may require additional considerations.

5 HPHT End Flange Initial Sizing Methodology

5.1 General This section provides guidance on how to develop the initial sizing of an API 6BX style fange using traditional hand calculations. These calculations should not be considered as a requirement during the verifcation process. Furthermore, use of these calculations do not exempt verifcation and validation of the fnal design.

5.2 Gasket Selection

Due to the complex behavior of seals, it is not possible to have a universal model, method or criterion for their design and verifcation.

NOTE See Annex A for an example of how an API 6BX gasket might be verifed for its capability.

5.3 Calculate Bolting and Flange Dimensions

5.3.1 Introduction

The method for calculating the bolting and fange dimensions is a fve-step process. Each step establishes a parameter or dimension as listed below.

— Hub Thickness (wall of pipe)

— Pressure Loading

— Size and number of bolts

— Raised face diameter

— Flange thickness

NOTE See Annex B for an example of the fve-step process.

5.3.2 Hub Thickness (Wall of Pipe)

The wall thickness of the hub may be determined using an appropriate pressure vessel wall calculation.

NOTE Eichenberg used Lame’s formula to determine the minimum wall thickness of the hub. The allowable tangential stress on the inner fber at working pressure was limited to 50 % of the specifed minimum yield strength of the fange body. While this method was acceptable at the time of his work, later advancements in pressure vessel technology have provided more robust means for proper wall sizing of a pressure vessel wall. Examples of these can be found in publications such as API 6X or API 1 7TR8.

5.3.3 Pressure Loading Calculate the total end load generated by internal pressure acting on the fange and gasket.

5.3.4 Size and Number of Bolts 5.3.4.1 Determine the minimum required total stud thread root area by dividing the total end load generated by internal pressure (see 5.3.3) at hydrostatic shell test condition by 83 % of the minimum specifed bolt yield strength

5.3.4.2 Select the size and number of bolts such that total stud thread root area is not less than the required total stud thread root area. The number of bolts should be a multiple of 4.

NOTE Calculating the bolt circle requires determining the fange dimensions and establishing practical clearances between the bolts, and between the bolts and the hub, to allow tool access. Refer to Taylor Forge’s “Modern Flange Design” for nominal dimensions [2] .

5.3.5 Raised Face Outside Diameter The raised face outside diameter may be calculated using the load generated by the chosen bolting assembled to 50 % of bolt yield strength assembly stress based on stress area.API TR 6AF3 pdf download.API TR 6AF3:2020 pdf free download