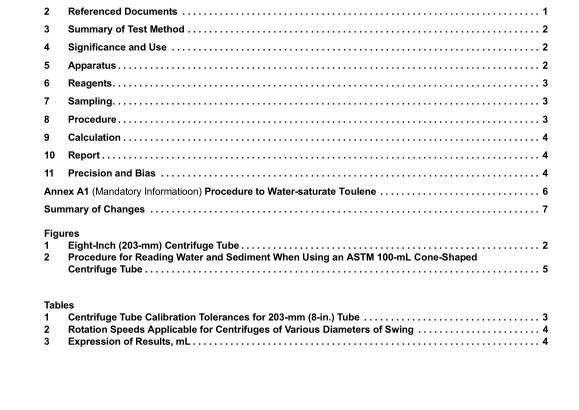

API MPMS 10.6:2013 pdf free download.Manual of Petroleum Measurement Standards Chapter 10.6 Standard Test Method for Water and Sediment in Fuel Oils by the Centrifuge Method (Laboratory Procedure)

5.2.2 Volumetrically verify or gravimetrically certify the accuracy of the graduation marks, in accordance with Practice E542 using equipment traceable through the National Institute for Standards and Technology (NIST) 6 or other national standards. Include the verification or certification for each mark through the 0.5-mL mark; of the 1, 1.5 and 2-mL marks; and of the 50 and 100-mL marks. Do not use the tube if the scale error exceeds the applicable tolerance in Table 1.

5.3 Bath—The bath shall be either a solid metal block bath or a liquid bath ofsufficient depth for immersing the centrifuge tube in the vertical position to the 100-mL mark. Provide the means for maintaining the temperature at 60 6 1°C (140 6 1.8°F). See Note 4.

N OTE 4—It has been observed for some fuel oils that temperatures higher than 60°C (140°F) may be required to obtain correct sediment and water content. If temperatures higher than 60°C are necessary, they may be used only with the consent of the parties involved. Water saturation of toluene may also be carried out at this higher testing temperature. (See Annex A1.)

6. Reagents

6.1 Toluene, conforming to the IP Specification for Methyl- benzenes (Toluenes) or to ISO 5272. (Warning—Flammable. Keep away from heat, sparks, and open flame. Vapor harmful. Toluene is toxic. Particular care must be taken to avoid breathing the vapor and to protect the eyes. Keep container closed. Use with adequate ventilation. Avoid prolonged or repeated contact with the skin.)

6.1.2 The solvent shall be water-saturated at 60 6 1°C (140 6 1.8°F) but shall be free of suspended water. See Annex A1 for the solvent-water saturation procedure.

6.2 Demulsifiers:

6.2.1 Where necessary, use a demulsifier to promote the separation of water from the sample, to prevent water from clinging to the walls of the centrifuge tube, and to enhance the distinctness of the water-oil interface.

6.2.2 When using a demulsifier, it should be mixed accord- ing to the manufacturer’s recommendations and should never be added to the volume of sediment and water determined. Always use the demulsifier in the form ofa demulsifier-solvent stock solution or be premixed with the solvent to be used in the test.

7. Sampling

7.1 Sampling is defined as all steps required to obtain an aliquot ofthe contents ofany pipe, tank, or other system and to place them into the laboratory test container.

7.2 Only representative samples obtained as specified in Practice D4057 (API MPMS Chapter 8.1) and Practice D4177 (API MPMS Chapter 8.2) shall be used for this test method. 7.3 Practice D5854 (API MPMS Chapter 8.3) contains additional information on sampling and homogenization effi- ciency of an untested mixer. Do not use this test method without strict adherence to Practice D5854 (API MPMS Chapter 8.3).

8. Procedure

8.1 Fill each of two centrifuge tubes (5.2) to the 50-mL mark with the well-mixed sample directly from the sample container. Using a pipette, add 50 mL of the water-saturated solvent (6.1). Read the top of the meniscus at both the 50 and 100 mL marks. Stopper the tubes tightly and shake vigorously until the contents are thoroughly mixed. Loosen the stoppers on the tubes and immerse the tubes to the 100-mL mark for 10 min in the bath maintained at 60 6 1°C (140 6 1.8°F).

8.2 Tighten the stoppers and again invert the tubes to ensure that the oil and solvent are uniformly mixed and shake cautiously. (Warning—In general, the vapor pressures of hydrocarbons at 60°C (140°F) are approximately double those at 40°C (104°F). Consequently, invert the tubes at a position below eye level so that contact will be avoided if the stopper is blown out.)API MPMS 10.6 pdf download.API MPMS 10.6:2013 pdf free download