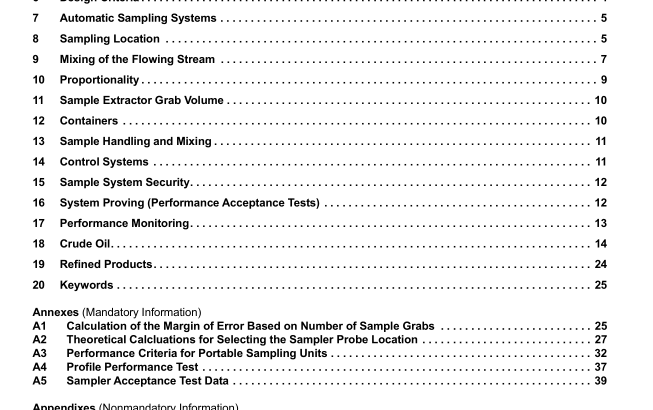

API MPMS 8.2:2015 pdf free download.Manual of Petroleum Measurement Standards Chapter 8.2 Standard Practice for Automatic Sampling of Petroleum and Petroleum Products

11. Sample Extractor Grab Volume

11.1 Sample extractors extract a wide variety of volumes per sample grab. When designing the sample system, consider the extractor grab volume. The extraction oflarger volumes per grab may require a larger container to provide the necessary resolution of the desired 9604 grabs per batch. (See Annex A1 on how to calculate the error when the grabs per batch are reduced.)

11.2 Larger grab volumes may also be required to fill a container to an acceptable level per Practice D5854 (API MPMS Chapter 8.3) during small-volume batches delivered at high flow rates. For the same overall volume collected, larger sample grab volumes will reduce the sample frequency and also the resolution of the sample.

11.3 Sample grab volumes should be repeatable within 65.0 %. The nominal grab volume (as determined by the sample probe manufacturer) is not necessarily the same as the actual grab volume. For purposes of establishing the sampling frequency for a batch, only the actual volume should be used.

11.4 The actual grab volume may be determined as an average by measuring 100 grabs into a suitably sized graduated cylinder. The volume contained in the cylinder at the end oftest shall be divided by 100 (or the number of grabs taken) to establish the actual grab volume.

11.4.1 For example, ifa sampler grabs 100 samples with the nominal grab size of 1.0 mL and an actual grab size of 1.2 mL, the end result would be 120 mL. In that situation, the person taking the sample could expect to observe anywhere from a low of 114 mL to a high of 126 mL during future verifications of the grab size.

12. Containers

12.1 Sample Containers:

12.1.1 A sample container is required to hold and maintain the composition of the sample in liquid form. This includes both stationary and portable containers, either ofwhich may be of variable or fixed volume design. If the loss of vapors will significantly affect the analysis of the sample, a variable volume type container should be considered. Materials of construction should be compatible with the petroleum or petroleum product sampled. In general, one sample container should be used for each batch. Sampling a single batch into two receivers should be avoided since this will increase the potential for error.

12.1.2 Fixed primary sample containers require local mix- ing. Perform flushing, cleaning, and inspection of the internal mixing system after each batch. Clean, flush, and inspect transportable primary containers either on location or at the laboratory. 12.1.3 The containers types will generally be either variable volume (constant pressure) or fixed volume (constant volume). Sample containers may be stationary or portable and shall allow for cleaning and inspection. When designed for off-site analysis, both in-line and slip stream sample loop-type sam- pling systems will have primary sample containers. Use a sample container designed to hold and maintain the composi- tion of the sample in liquid form. Stationary systems typically require local product mixing for any potentially nonhomoge- neous product. Stationary sample containers remain perma- nently attached to the sampling system and are not intended to be removed while portable sample containers are removed from the sampling system and transported to the laboratory for mixing and analysis.

12.1.4 Both the design and materials of a sample container shall be tailored for the application. Container components including gaskets and O-rings, couplings, closures, seals, and relief valves should be assessed when reviewing the compat- ibility of container materials. The materials used in the construction of the sample container shall be compatible with the fluids to be collected and retained, as well as not compro- mising the properties of interest to be tested. Some contami- nants may be adsorbed or absorbed by typical container materials. Special coatings or surface preparations may be required to avoid such effects.

12.1.5 The design of the sample container shall facilitate mixing of the sample to obtain a representative sample. The sample container may require special construction details to obtain an aliquot or test specimen for the purpose of perform- ing an analysis and sample retention. Some analyses require that the sample not be exposed to air which will impact the method of sealing the container as well as other design considerations.

N OTE 2—If an aliquot or test specimen is to be drawn directly into the testing device, the primary sample container may need to have the capability of being homogenized. API MPMS 8.2 pdf download.API MPMS 8.2:2015 pdf free download