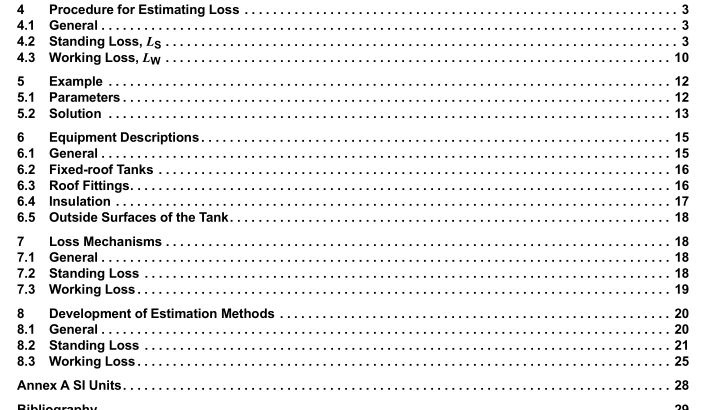

API MPMS 19.1:2017 pdf free download.Manual of Petroleum Measurement Standards Chapter 19.1 Evaporative Loss from Fixed-roof Tanks

6.3.2 Pressure-vacuum (PV) vents are mounted on the tank roof to provide sufficient venting capacity to protect the tank from experiencing pressure or vacuum greater than the tank design pressure or vacuum, respectively. When a pressure occurs within the tank vapor space that exceeds the pressure set point, the PV vent opens to release vapors from the tank until the pressure is reduced below its set point. When a vacuum occurs within the tank vapor space that exceeds the vacuum set point, the PV vent opens to admit air into the tank until the vacuum is reduced below its set point.

API 2521 [11] describes the use of PV vents on fixed-roof tanks and presents factors to consider in their selection and maintenance. API 2000 [8] describes the sizing requirements for PV vents on storage tanks and addresses both normal and emergency venting conditions. PV vents on atmospheric pressure fixed-roof tanks are usually set at 0.75 in. of water column, or approximately 0.5 oz/in. 2 .

The required normal pressure venting capacity or vacuum venting capacity should accommodate breathing and product movement without exceeding the design pressure or design vacuum of the tank. Open vents of the mushroom or return-bend (gooseneck) type are sometimes used on fixed-roof tanks storing low-volatility liquids. Gauge-hatch/Sample Wells

6.3.3 Gauge-hatch/sample wells provide access for manually gauging the stock level in the tank and for taking samples of the tank contents. Gauge-hatch/sample wells typically consist of a pipe penetration on the tank roof that is equipped with a self-closing cover. Gauge-hatch/sample wells are usually located by the gauger’s platform, which is at the top of the tank shell. Some vapor loss may occur during manual gauging and stock sampling operations, during which time the gauge-hatch/sample well cover is open. This loss can be minimized by reducing the period of time that the cover is left open. Float Gauges

6.3.4 Float gauges are used to indicate the stock level in the tank. Float gauges consist of a float that rests on the liquid surface and is connected to a liquid level indicator mounted outside the tank shell by a cable or tape that passes through a guide system. The cable or tape passes through the tank roof and is normally contained in a sealed conduit. Roof Manholes

6.3.5 Roof manholes provide access to the tank interior for inspection or maintenance. Roof manholes normally consist of a circular opening in the tank roof with a vertical neck attached to the roof and a removable cover. The opening is sized to provide for the passage of personnel and materials through the roof.

6.4 Insulation Some stocks have to be stored in a heated or cooled condition to permit proper handling. Such tanks may require insulated shells and/or roofs, depending upon the local climate, stock properties, and storage temperature.

Insulation can reduce the standing loss by reducing the daily range in vapor space temperature driven by ambient heat input or loss to the tank. Storing hot stock does not eliminate standing loss, but insulating the tank regardless of whether the stock is heated does reduce the standing loss driven by the ambient diurnal temperature cycle. Conversely, insulating a tank that stores hot stock increases working loss by reducing heat loss, thereby maintaining a higher liquid surface temperature.

6.5 Outside Surfaces of the Tank Painting the tank shell and roof reduces evaporative loss and preserves the tank. Highly reflective surfaces, such as mill-finish aluminum or surfaces painted white, result in lower tank metal temperatures and lower heat input to the tank, reducing the standing loss. Tank paint inspection and maintenance preserve the paint reflectance and reduce corrosion of the tank. Unpainted aluminum dome roofs provide a highly reflective surface while avoiding the maintenance required for paint.

7 Loss Mechanisms

7.1 General Evaporation is the natural process in which a liquid is converted to a vapor. Through evaporation, all liquids establish an equilibrium concentration of vapors above the liquid surface. Every liquid stock has a finite vapor pressure that depends on the surface temperature and composition of the liquid and that causes the liquid to evaporate. Under static conditions, an equilibrium vapor concentration is established, after which no further evaporation occurs. However, fixed-roof tanks are exposed to dynamic conditions that disturb this equilibrium, causing additional evaporation. These dynamic conditions are responsible for continued evaporation, resulting in stock loss and atmospheric emissions. Evaporation loss from fixed-roof tanks occurs when the evaporated vapor escapes the tank and goes into the atmosphere. The total evaporative loss from a fixed-roof tank is the sum of the standing loss and the working loss.API MPMS 19.1 pdf download.API MPMS 19.1:2017 pdf free download