API SPEC 19V:2019 pdf free download.Subsurface Completion Isolation (Barrier) Valves and Related Equipment

5.7.2 Alternate (Barrier) Leakage Test Acceptance Criteria The user/purchaser may select this alternate (reduced) leakage test acceptance criteria for products where design validation level V1 H, V1 , or V2 has been selected. See Annex F for the detailed requirements.

5.7.3 Performance Envelope for V2 The user/purchaser may request a performance envelope supplied to illustrate the combined effects of pressure, temperature, and axial loads for V2 SCIVs; see Annex E.

5.7.4 Additional Validation Testing The user/purchaser may select additional validation testing performed as defined in Annex G and/or in Annex H.

5.7.5 Additional Quality Requirements The user/purchaser may require the performance of additional quality inspection operations.

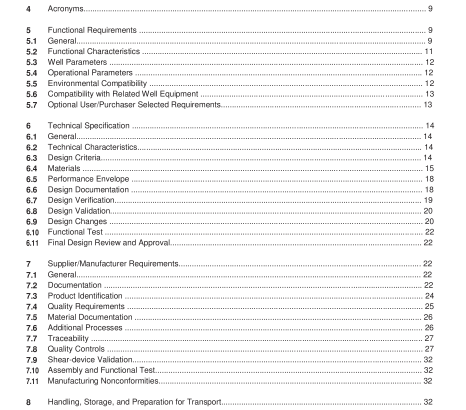

6 Technical Specification

6.1 General The supplier/manufacturer shall provide the user/purchaser with a technical specification that conforms to the requirements defined in the functional specification, or identifies in detail where variance(s) are offered. The supplier/manufacturer shall also provide the user/purchaser with the technical and manufacturing data required by 7.2. In cases where the user/purchaser specifies material(s) of construction, deviations from such material(s) of construction shall require user/purchaser notification.

6.2 Technical Characteristics The SCIV and SCIV-related tools shall perform in accordance with the functional specification, as stated in Section 5, and within the limitations defined in the product-specific operating manual and design criteria.

6.3 Design Criteria

6.3.1 General SCIV and SCIV tool designs shall permit prediction and repeatability of conditions required for opening and/or closing. SCIV products shall be designed to meet the design validation requirements and the requirements of the functional specification. Final approval of the design shall be performed and documented by a qualified person(s) other than the person who created the original design.

6.3.2 Design Requirements

6.3.2.1 General The supplier/manufacturer shall establish internal yield pressure, external pressure, minimum tensile/compressive strength ratings (excluding end connections), geometrical dimensions, and the operational capabilities necessary to meet the requirements of this specification. External pressure, tensile, compression, and internal chamber ratings shall be established based on design calculations or full-scale testing using supplier/manufacturer approved methods by a qualified person(s).

The supplier/manufacturer shall identify all related tools necessary for the full functionality of the SCIV. The design requirements for the related tools and the interface with the specific SCIV shall conform to the functional specification. SCIV tools shall be designed and manufactured according to the requirements defined for QL2. Temperature, environment, material properties, and combined loading effects on all materials used in SCIV products shall be considered when establishing the rated pressures and load capabilities.

The design shall take into account the effects of pressure containment and pressure-induced loads. Where applicable, specialized and/or intermittent conditions, such as pressure testing with temporary test plugs, shall also be considered in the design.

The additive dimensional tolerances shall be such that proper operation of the SCIV product is assured. SCIV products and components conforming to this specification shall be manufactured according to drawings and specifications that contain no substantive changes from those of the SCIV product that passed the applicable validation test. Components and welds shall be identified as Type 1 , Type 2, or common hardware in the design documentation.

6.3.2.2 Temperature and Environment Considerations SCIV product design shall take into consideration the effects of temperature on all components. The upper temperature limit shall be the lowest high-temperature rating of any component of the SCIV. The lower temperature limit shall be the highest low-temperature rating of any component of the SCIV. De-rating of metal mechanical properties shall be in accordance with ASME BPVC, Section II, Part D or a reference approved by a qualified person of the supplier/manufacturer.

The supplier/manufacturer shall utilize temperature de-rated yield strength test results for each metallic material corresponding to the maximum rated temperature of the valve. Metal mechanical properties de-rating shall be verified and documented by a qualified person.API SPEC 19V pdf download.API SPEC 19V:2019 pdf free download