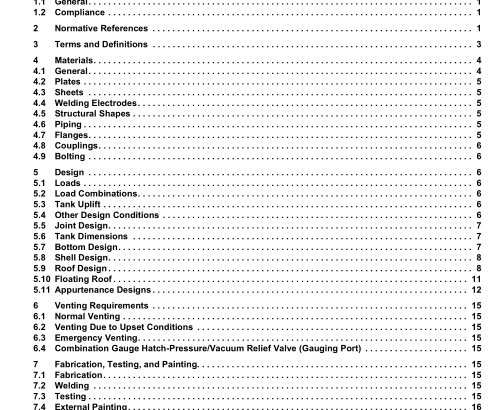

API SPEC 12F:2019 pdf free download.Specification for Shop-welded Tanks for Storage of Production Liquids

5.1 Loads

5.1.1 The design vacuum specified in Table 1 .

5.1.2 The maximum pressure specified in Table 1 .

5.1.3 The hydrostatic pressure from liquid inside the tank.

5.1.4 A 1 93 km/h (1 20 mph) 3-second gust wind speed applied in accordance with ASCE 7-1 6 (Exposure C).

5.1.5 A ground snow load of 1 .44 kPa (30 psf) applied in accordance with ASCE 7-1 6.

5.2 Load Combinations

5.2.1 A full tank of liquid (1 .0 SG), the pressure stated in 5.1 .2, and no wind.

5.2.2 460 mm (1 8 in.) of liquid (0.7 SG), the wind stated in 5.1 .4, and no internal pressure.

5.2.3 A ground snow load as stated in 5.1 .5 and a vacuum of 0.43 kPa (1 oz/in. 2 )

5.3 Tank Uplift

Self-anchored tanks complying with this specification may experience up to approximately 25 mm (1 in.) of uplift for some load combinations in 5.2.

5.4 Other Design Conditions

5.4.1 Tanks with loads other than those stated in 5.1 or load combinations other than those stated in 5.2 are outside the scope of this specification and should be designed in accordance with other appropriate standards, including but not limited to API 650, Annex J. 5.4.2 Specification 1 2F tanks may be mechanically anchored; however, the design and details used to anchor the tanks is outside the scope of this specification.

5.4.3 The purchaser should refer to API 650, Figure 4.1 b to determine the minimum design temperature for the material selected in 4.2 or 4.3.

5.4.4 The maximum design temperature is 93 °C (200 °F). If an internal tank lining is installed into the tank, the purchaser should ensure that the selected lining is suitable for the design temperature

5.4.5 The tank roof is not designed to serve as a work platform outside of the provisions noted in 5.1 1 .4 and the cautionary note in 5.1 0.1 .

5.5 Joint Design Size of Weld The size of a weld shall be based on the following dimensions.

a) Groove weld: The joint penetration (depth of chamfering plus the root penetration when specified).

b) Fillet weld: For equal leg fillet welds, the leg length of the largest isosceles right-triangle that can be inscribed within the fillet weld cross-section. For unequal leg fillet welds, the leg lengths of the largest right-triangle that can be inscribed within the fillet-weld cross section. Joint Restrictions The following restrictions on type and size of joints or welds shall apply.

a) Tack welds shall not be considered as having any strength value in the finished structure.

b) The minimum size of fillet welds shall be as follows: Plate 4.8 mm ( 3 / 1 6 in.) in thickness, full-fillet welds; plates over 4.8 mm ( 3 / 1 6 in.) thick, not less than one-third the thickness of the thinner plate at the joint, with a minimum throat thickness of 4.8 mm ( 3 / 1 6 in.).

c) Single-welded joints shall not be permissible on tank bottoms, shells, roofs, or any pressure-containing parts such as nozzles, piping, or other components integral to the tank. Seam Layout Welds of couplings, cleanouts, other connections or appurtenances, and bottom plate joining butt joints shall not be placed in, or align within, 25 mm (1 in.) of shell or bottom weld seams. Reinforcing plates (if used) shall not overlap plate seams. If there is no other feasible option and the purchaser accepts the design, circular shell openings and reinforcing plates (if used) may be located in a horizontal or vertical groove-welded shell joint, provided that the minimum spacing dimensions of API 650, Section 5.7.3 are met.

5.6 Tank Dimensions Tanks under this specification shall be furnished in the sizes given in Table 1 .

5.7 Bottom Design Type The tank bottom shall be flat, Type A (unskirted), or Type B (skirted) cone design, as specified on the purchase order. Type A and Type B cone bottoms shall conform to Figure 2 and Figure 3, respectively. With agreement of the purchaser, Type A cone bottom tanks may be supplied without the optional sump (E), as noted in Figure 2.API SPEC 12F pdf download.API SPEC 12F:2019 pdf free download