API RP 1181:2019 pdf free download.Pipeline Operational Status Determination

5.3.1 General

An idled pipeline has been shut down, isolated from all sources of hazardous liquid or natural or other gas (capped or blinded), the system purged of combustibles or maintained with a blanket of natural gas at low pressure, and removed from service. CP should be maintained on idled lines.

An idled line may be returned to active service. A pipeline should be considered idled when the following activities are performed:

— Line should be cleaned based on the operator’s procedures. Liquid pipelines shall be purged with an inert material, such as nitrogen or inhibited water.

— Natural gas pipelines may be purged with air, an inert material, or a blanket of natural gas at a low pressure where the volume of gas is so small that there is no potential hazard.

— Caution should be taken when using air to purge a natural gas line.

— Removal of pipeline components is acceptable (i.e. motor operators, electrical components, etc.)

— Breakout tanks shall be physically isolated from the idled pipeline system or emptied of hazardous product.

— A breakout tank is considered idled when it is emptied of hazardous liquids and physically disconnected from any active pipeline system.

5.3.2 Maintenance and Inspection Activities on Idled Pipelines

Maintenance and inspection activities that should be performed on idled pipelines include but are not limited to:

— CP inspections and maintenance;

— atmospheric corrosion inspections;

— navigable waterway crossing inspections;

— damage prevention activities:

— public awareness programs;

— One Call;

— line marker maintenance.

5.3.3 Deferred Maintenance and Inspection Activities on Idled Pipelines

Maintenance and inspection activities that can be deferred on idled pipelines until the line returns to active status or abandoned include but are not limited to:

— overpressure and overfll safety device inspections;

— valve inspections;

— emergency shutdown device inspections;

— ROW maintenance;

— ROW surveillance;

— IMP activities;

— internal corrosion control;

— management of cased pipeline sections;

— leak detection and leakage surveys;

— control room management activities associated with the idled pipeline;

— frefghting equipment inspection and maintenance;

— inspections of idled breakout tanks;

— remedial maintenance, such as:

— atmospheric recoat;

— exposure remediation;

— continual surveillance for class location changes of gas pipelines.

5.3.4 Documentation

Documentation activities for idled pipelines include:

— documenting details of the purging and cleaning activities as applicable;

— documenting inspection, maintenance, and repair activities being performed and those being deferred;

— maintaining management of change (MOC) documentation showing pipeline is idled;

— documenting communication with the appropriate regulatory jurisdiction as applicable.

5.3.5 Returning an Idled Line to Service

Prior to returning an idled line to service, operators shall develop and implement a written return-to-service plan, including:

— a risk assessment;

— an integrity verifcation plan;

— a review of maintenance and CP records;

— a schedule to resume deferred inspection and maintenance.

If a line was idled and is returned to active service, operators shall confrm integrity of the pipeline, including use of integrity testing such as leak tests, hydrotests, and/or in line inspections.

Operators shall ensure that all deferred inspection and maintenance activities that could affect the safe operation of the line are addressed prior to returning the line to active service.

Deferred activities that do not affect the safe operation of the line should be addressed as soon as practical after returning the line to active service.

Appropriate notifcations shall be made as required by the regulatory agency with jurisdiction over the pipeline.

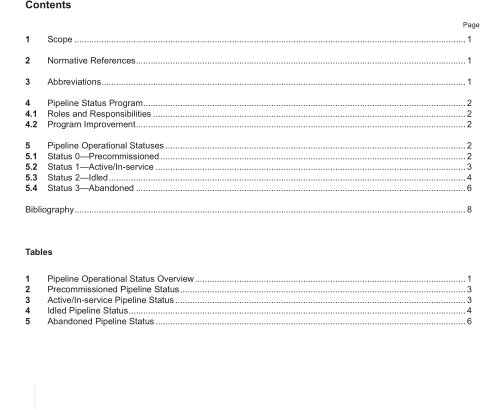

5.4 Status 3—Abandoned

Refer to Table 5 for information on abandoned pipeline status.

5.4.1 General Pipeline has been shut down, isolated from other in-service lines, connections to all sources of hazardous liquid or natural or other gas are capped or blinded, system is purged of combustibles, sealed, and permanently removed from service.

Some or all the pipeline may have been physically removed.

Additionally:

— Line is cleaned based on the operator’s procedures.

— Line is purged with an inert material, such as nitrogen or water.

— Line pressure is not maintained.

— ROW maintenance (mowing, trimming, etc.) is not required.API RP 1181 pdf download.API RP 1181:2019 pdf free download