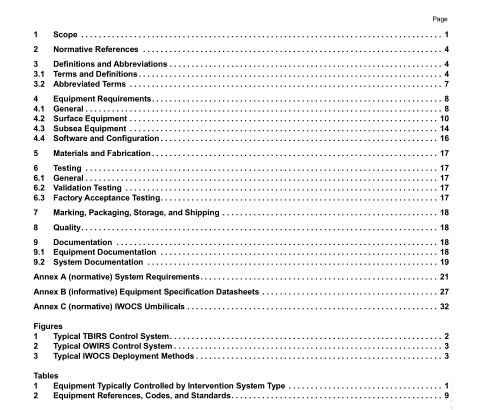

API RP 17G5:2019 pdf free download.Subsea Intervention Workover Control Systems

3.2 Abbreviated Terms

For the purposes of this document, the following abbreviations apply.

BOP blowout preventer

CIU chemical injection unit

EDP emergency disconnect package

EFAT extended factory acceptance test

EH electro-hydraulic

EPU electrical power unit

EQD emergency quick disconnect

ESD emergency shutdown

FAT factory acceptance test

HMI human–machine interface

HPU hydraulic power unit

IR insulation resistance

IWOCS intervention workover control system

LARS launch and recovery system

MCS master control station

MUX multiplex

OWIRS open-water intervention riser system

P&ID piping and instrumentation diagram

PSD process shutdown

RCM riser control module

ROV remotely operated vehicle

SCSSV surface-controlled subsurface safety valve

SEM subsea electronics module

SSTTA subsea test tree assembly

TBIRS thru-blowout preventer intervention riser system

UPS uninterruptible power supply

VIV vortex-induced vibration

WCM workover control module

WCP well control package

XT subsea tree

4 Equipment Requirements

4.1 General

4.1.1 General Requirements

Requirements in this section shall apply to all surface and subsea equipment covered by this document.

Some equipment contains functionality to support operation of safety class control functions. For these pieces of equipment, the following requirements are specific to the safety class control functions:

― risk of unintended operation of safety class control functions shall be mitigated;

― safety class control functions shall be protected by interlocks, protective covers, or isolation of dedicated control lines;

― visible and/or audible indication of execution of safety class control functions shall be provided.

Manufacturer shall define a service condition for all IWOCS equipment for storage, shipping, and operation.

Service conditions should be in accordance with API 17F.

NOTE IWOCS for TBIRS operations may require higher temperature ratings than given in API 17F.

Design of equipment shall comply with hazardous area requirements necessary for safe operation in the planned installation location.

Equipment shall conform to the requirements from API 17G for pad eyes and lifting devices. Equipment should be provided with lifting certifications appropriate for the region of operations.

For equipment designed to accept contaminated return fluid, returns shall be routed via a bleed header toa designated return. Equipment designed to accept contaminated return fluids shall assess the need forisolations, flame arrestors, gas detectors, over-pressure protection, and applicable alarms depending on the type of fluid contaminants.

Table 2 highlights subsea IWOCS equipment included within the scope of this recommended practice.

4.1.2 Pressure Ratings

Pressure ratings for all IWOCS equipment shall conform to the requirements in API 17F for the hydraulic power system.

4.1.3 Accumulators

Accumulators used for safety class control functions shall be sized in accordance with API 16D using the appropriate sizing method for the location and type of safety class control function (e.g. method C for rapid discharge applications). Safety class control functions shall use dedicated accumulator volumes (i.e. accumulator volumes for safety class control functions shall not be impacted by use of normal class control functions).

Design of accumulators shall conform to the ASME Boiler and Pressure Vessel Code, Section VIII, Division 1, BS EN 14359, ISO 10945, or any other agreed-upon pressure vessel or accumulator code or standard.

NOTE For the purposes of this provision, BS 7201-2 is the equivalent of ISO 10945.

Accumulator sizing shall also take into account the following:

― system leakage allowances before service intervals;

― subsea pressures (including any external pressure due to water depth);

― temperature environment (including elevated temperatures for in-riser applications);

― ability to be recharged during operation;

― volume to operate safety class control functions without assistance from the charging system;

― pressure to actuate shearing valves or rams with shearable element in the wellbore.

Accumulators used for surface tree valves shall provide the power fluid volume and pressure required to complete safety class control functions plus sufficient volume to perform one close cycle plus 25 % close volume margin of each valve.API RP 17G5 pdf download.API RP 17G5:2019 pdf free download