API 588:2019 pdf free download.Recommended Practice for Source Inspection and Quality Surveillance of Fixed Equipment

This recommended practice (RP) covers the process of specifying the necessary quality surveillance of materials, equipment, and fabrications being supplied for use in the oil, petrochemical, and gas Industry, including upstream, midstream, and downstream segments. This RP may be used as the basis for providing a systematic approach to risk-based source inspection to provide confdence that materials and equipment being purchased meet the minimum requirements as specifed in the project documents and contractual agreements. The activities outlined in this RP are not intended to replace the manufacturer’s/fabricator’s own quality systems, but rather are meant to guide SIs acting on behalf of the purchaser to determine whether manufacturer’s/fabricator’s own quality systems have functioned appropriately, such that the purchased equipment and materials will meet contractual agreements.

This RP focuses primarily on pressure-containing and structural equipment (fxed equipment), including but not limited to vessels, columns/towers, heat exchangers, piping, valves, pressure-relief devices, tubulars, and supporting structural fabrications. The principles of the document can be applied to other equipment disciplines. This document assumes that suppliers/vendors (S/V) have been pre-qualifed by a systematic quality review process of their facilities and quality processes to determine if the facility has the ability to meet the requirements of the contractual agreements. That process generally leads to a list of pre-approved S/Vs deemed acceptable to the supply chain management of the purchaser who are capable of meeting the requirements of the contract prior to it being placed. S/Vs on such a list will normally have an acceptable quality process already in place that meets the requirements of the contract. An approved S/V list may also indicate that S/Vs have the technical skills and can meet the SCM commercial terms and conditions.

The purpose of source inspection in such a case is simply to verify that the S/V quality processes are working as they should and to verify that certain critical steps in the inspection and test plan (ITP) have been satisfactorily accomplished prior to fabrication completion and/ or shipping. The primary purpose of this RP is to summarize the basic body of knowledge that the source inspector typically needs to know to perform as a source inspector for fxed equipment. A secondary purpose is to assist candidates intending to take the API Source Inspection Examination to become certifed source inspectors. This RP outlines the fundamentals of source inspection and may be useful to all personnel conducting such activities to perform their jobs in a competent and ethical manner. For more information on how to apply for Source Inspection Certifcation, please visit the API website at www.api.org/si and follow the work process shown in Figure 1.

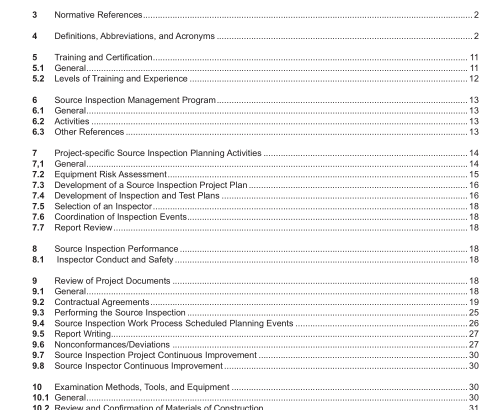

2 Introduction The source inspection work process follows the Plan–Do–Check–Act circular process frst popularized in the 1950s by Edward Deming. The “Plan” part of source inspection is covered in Sections 6 and 7 of this RP and involves the source inspection management systems, source inspection project plan, and the inspection and test plan (ITP). The “Do” part is covered in Sections 8, 9, and 10, and involves implementing the ITP, participating in scheduled source inspection work process events, fling nonconformance reports (NCRs), and source inspection report writing. The “Check” part, covered in Section 9.7, involves reviewing all the source inspection activities that occurred in the “Plan” and “Do” parts to see what went well and what should be improved based on the results of that review. Finally, the “Act” part (sometimes called the “Adjust” part), covered in Section 9.8, involves implementing all the needed improvements in the “Plan” and “Do” parts before they are implemented on the next source inspection project.API 588 pdf download.API 588:2019 pdf free download