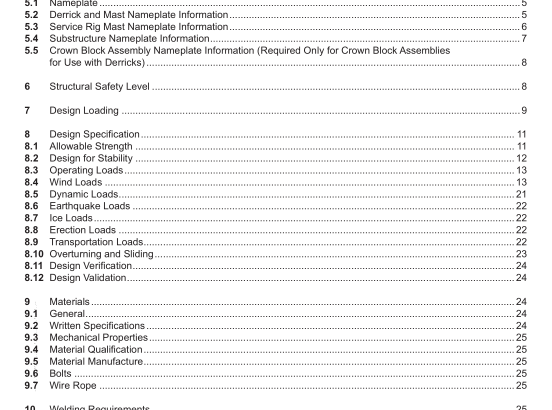

API 4F:2020 pdf free download.Specifcation for Drilling and Well Servicing Structures

8 Design Specifcation

8.1 Allowable Strength

8.1.1 General

The steel structures shall be designed in accordance with the Allowable Strength Design code in ANSI/AISC 360-16, except as further specifed in this standard. ANSI/AISC 360-16 shall be used in determining allowable member strength. Use of load factor and resistance design (LFRD) is not allowed. ANSI/AISC 360-16 shall be used for determination of allowable member strength except that current practice and experience do not dictate the need to follow ANSI/AISC 360-16 for “members and their connections subject to fatigue loading” (Section B3.11) unless specifed by the purchaser and for the consideration of secondary loads.

NOTE Derricks, masts, and substructures for drilling rigs fall outside the defned scope of the ANSI/AISC 360-16 specifcation. AISC recognizes this and recommends that the use of the AISC specifcation outside of the defned scope be used with engineering judgement as it relates to the specifc industry.

For the purposes of this standard, axial loads (tension or compression) are defned as primary loads in individual members of a latticed or trussed structure. Moments in the individual members of a latticed or trussed structure resulting from elastic deformations and rigidity of joints are defned as secondary loads.

These secondary loads may be taken to be the diferences between loads from an analysis assuming fully rigid joints, with loads applied only at the joints, and those loads from a similar analysis with pinned joints. Loads arising from eccentric joint connection, or from transverse loading of members between joints, or from applied moments shall be considered primary loads. When axial loads are the intended primary loads, allowable member strength may be increased by 10 %.

This shall apply to members that have a plastic section modulus/elastic section modulus (Z/S) ratio of 1.2 or less when secondary loads are computed and added to the primary loads in individual members, for all loadings except earthquake.

The 10 % increase in allowable member strength shall not be used when the Z/S ratio exceeds 1.2. The Z/S ratio is taken about either the major or minor member axis for the direction of the applied moment. Required strength due to primary loads shall not exceed the maximum allowable member strength. The increase in allowable member strength when secondary loads are considered may be taken in addition to the increases allowed in 8.1.2.

The allowable member strength is defned in ANSI/AISC 360–16 as the nominal strength ( R n ) of the member divided by a safety factor ( Ω ). Allowable Strength = R n / Ω. ANSI/AISC 360-16, Chapters D through K give further defnition of the nominal strength and safety factor for the applicable limit states. Earthquake loading and the related allowable strength are addressed specifcally in 8.6. Ice Loading and related allowable strength are addressed specifcally in 8.7.

8.1.2 Wind and Dynamic Allowable Strength Increases For operating and erection conditions, allowable member strength shall not be increased (strength modifer = 1.0 ) over the basic allowable member strength defned in 8.1.1. For transportation conditions, allowable member strength may be increased one-third (strength modifer = 1.33 ) over the basic allowable member strength defned in 8.1.1.

For the unexpected and expected design storm conditions, allowable member strength may be increased one- third (strength modifer = 1.33 ) over basic allowable member strength defned in 8.1.1.

For purposes of defning the nameplate graph of allowable static hook load vs wind velocity required by 5.2 n) or 5.3 o), a linear transition from a strength modifer of 1.0 for operating cases to 1.33 for the unexpected storm case may be used.API 4F:2020 pdf free download