API St 622:2011 pdf free download.Type Testing of Process Valve Packing for Fugitive Emissions

6 Packing Materials Test The packing materials test considers weight loss, density, lubricant content, and leachables as per the procedures outlined below. For new configurations, test packing shall be selected at random from a minimum production lot as supplied by the manufacturer. For existing configurations, test packing shall be provided by a blind selection of production product from the manufacturer’s normal distribution network. Validation of the random or the blind selection of process shall be provided to the testing lab. Random selection does not apply to testing of prototype material.

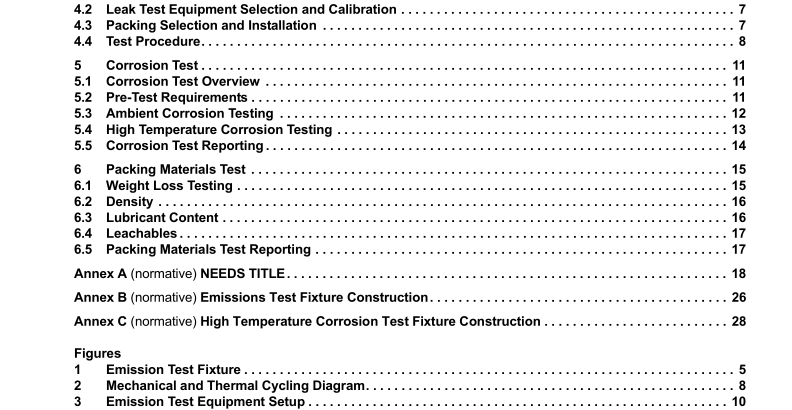

6.1 Weight Loss Testing

6.1.1 Graphite Foil Weight Loss Test Procedure Weight loss of graphite packing rings shall be determined as follows.

a) Conducted in a controlled environment using suitable testing equipment.

b) Flexible graphite sample size shall be between 0.5 grams and 3.5 grams.

c) Three samples shall be tested. Record weight of each sample.

d) Samples shall be preconditioned for one hour at 150 °C (302 °F) with a ramp up speed of 10 °C (18 °F) per minute. Record dried sample weight and use for weight loss percentage calculations.

e) After one hour, the samples shall continue ramping up at 10 °C (18 °F) per minute to the final test temperature of 593 °C (1100 °F) ± 2 °C (3.6 °F).

f) This test temperature shall be held for 24 hours and then cooled.

g) Weigh samples after cooling and record weight.

NOTE TGA testers have the capability to weigh samples without being removed from the heat source. This is an acceptable alternative to cooling and weighing.

h) Determine the percent weight loss of each sample and record.

i) Average the results and a weight loss greater than 15 % is not acceptable. NOTE This test method also follows an established testing standard, FSA-G-604-07 Method B, issued by the Fluid Sealing Association.

6.1.2 Braided Packing Ring Weight Loss Test Procedure Weight loss of braided packing rings shall be determined as follows.

a) Conducted in an oven with full exposure to air (Oxygen-rich environment).

b) Select three test rings of a sample packing set. If the packing set is comprised of more than one type of packing ring, each type shall be tested.

c) Record weight.

d) Preheat oven to 150 °C (300 °F).

e) Place sample in oven for one hour.

f) Remove samples, cool to room temperature, and record weight.

g) Increase oven temperature to 260 °C (500 °F) and repeat step e and step f.

h) Increase temperature to 538 °C in 56 °C (1000 °F in 100 °F) increments, repeating step e and step f after each increase.

i) Discontinue test if weight loss exceeds 50 %.

6.2 Density Packing Density shall be determined by dividing the sample weight by the sample volume, with the sample volume determined as follows:

a) Braided packing volume shall be determined by measuring the sample length, width and thickness. Volume = Median Length × Width × Thickness

b) Die-formed packing (ring form) volume shall be determined by the following equation: Volume = [(Ring OD 2 – Ring ID 2 ) × Ring Thickness × π] / 4 where OD is the outside diameter; ID is the inside diameter.

6.3 Lubricant Content

6.3.1 Polytetrafluoroethylene (PTFE) Content PTFE content shall be established by determining the percentage total fluorine in the packing, and comparing with a base fluorine percentage of 76, as follows:

a) determine total percent of fluorine content using ASTM D1179 or ASTM D4327, and

b) divide total percent of fluorine as obtained in a) by 0.76 to obtain the approximate percent of PTFE content.

6.3.2 Wet Lubricant Wet lubricant percentage shall be determined by dividing the “weight of the lubricant extract” by the “original sample weight” and multiplying by 100. The procedure shall be as follows.

a) Cut samples into short lengths, and record the total sample weight (approximately 15 grams is required).

b) Place cut samples into an extraction thimble and insert thimble into Soxhlet extraction unit that is nearly filled with a solvent, such as methylene chloride.

c) Turn on water flow through the condenser and bring the methylene chloride to a moderate boil through the use of the “low” setting on a hot plate. Extract for approximately 16 hours.API St 622 pdf download.API St 622:2011 pdf free download