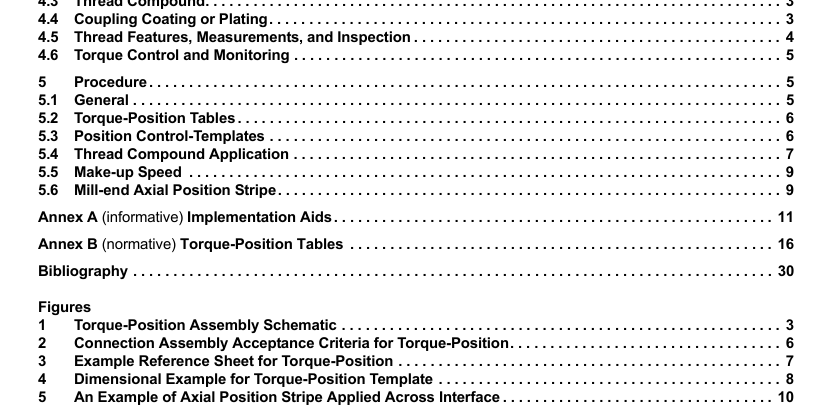

API TR 5TP:2013 pdf free download.Torque-Position Assembly Guidelines for API Casing and Tubing Connections

4 Background

4.1 Torque-Position Application

Torque-position is a precision assembly method for assembling API connections. The connection is made up within a prescribed torque range using hydraulic power tongs, such that the face of the coupling progresses into a position band stenciled on the OD of the pipe. Connections that do not meet both the torque and position criteria are rejected.

The use of torque-position connection assembly procedures and the application of this document shall be by agreement between the user/purchaser and the manufacturer. These guidelines shall be used at the designated mill, processor’s facility, and rig site in order to ensure appropriate assembly of the connections (see Figure 1 and Figure 2).

4.2 API Connection

Sealing Mechanism API connections rely on contact pressure on the thread flanks to form an effective seal and a particulate thread compound to plug the root-to-crest gap on 8-round connections (SC, LC, EU) and thread flank gaps on buttress connections. In an interference connection, the threads on both the pin and coupling are cut at a matching angle or taper. As the connection is made up, the pin becomes wedged into the coupling creating contact pressure.

This contact or bearing pressure is the sealing mechanism for this connection. To form a leak-resistant seal, the bearing pressures on the thread flanks must be greater than the internal pressure. In addition to thread flank bearing pressures, it is also necessary to use a thread compound and a suitable coating or plating on the coupling threads to form a leak-resistant seal.

This combination of thread compound and coating or plating prevents the migration of gas or fluid through the root-to-crest and thread flank clearances. Sealing performance of some sizes and connections is enhanced by using modified seal-ring couplings conforming to API 5CT, SR13. Seal rings are recommended for these connections because of the high make-up torques that would be required without them. In a seal-ring coupling, a groove is cut in the coupling and a nonmetallic ring is installed in the groove prior to any thread compound application and connection assembly.

4.3 Thread Compound

Thread compound serves three basic functions:

1) seals the thread clearances in the thread profile,

2) lubricates the threads during make-up, and

3) resists galling that results from metal-to-metal contact

Most thread compounds consist of particles suspended in carrier grease. The types and ratios of the particles generally determine the performance of a thread compound.

Torque-position technology was developed using API 5A3 Reference compound (formerly called API Modified) for 8-round and non-4T buttress connections and a PTFE-based thread compound for BC 4T make-up.

4.4 Coupling Coating or Plating API couplings intended for assembly with torque-position parameters should have a phosphate coating or tin plating on the threads to prevent galling during assembly and to assist in providing seal integrity. The type of coating or plating used will affect the assembly torque.

Torque values for tin-plated couplings are much lower than for phosphate coated couplings; therefore, a separate torque range is given in the tables. The torques tabulated for sealring couplings assume phosphate-coated threads and the BC 4T assembly requires tin- plated coupling threads.

Phosphate coatings are typically applied to a coupling to a thickness of less than 0.001 in. With tin-plated couplings, both the thickness and uniformity of the tin should be carefully checked. Lack of uniformity can cause erratic make-up, galling, and potential leak paths. Tin plating should be applied to a thickness between 0.0025 in. and 0.0045 in.

4.5 Thread Features, Measurements, and Inspection Maintaining all thread parameters set forth by API 5B will ensure downhole performance and smooth assembly operations. Significant variations in thread height, lead, and taper can affect the assembly torque and subsequent performance.API TR 5TP pdf download.API TR 5TP:2013 pdf free download