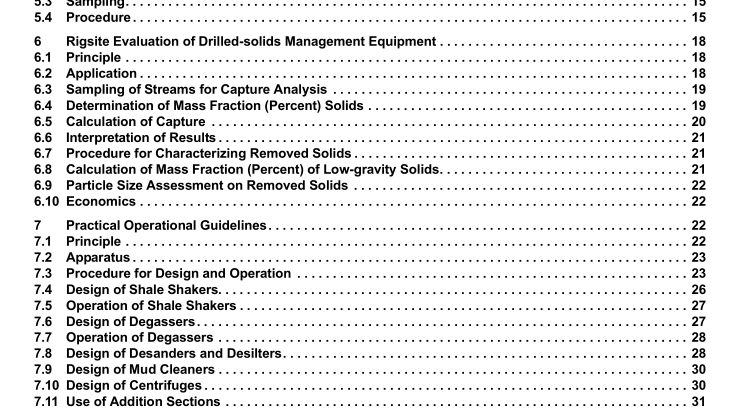

API RP 13C:2014 pdf free download.Recommended Practice on Drilling Fluid Processing Systems Evaluation

7.3.8.3 An adjustable riser or overflow shall be installed on the downstream side of the equalizer between the removal and addition sections to permit control of the fluid level in the removal section.

7.3.9 Tank Agitation

7.3.9.1 Drilling fluid tank agitation is necessary to prevent solids accumulation in the tank. With the sole exception of the sand trap, all compartments shall be mechanically agitated.

7.3.9.2 If mud guns are chosen instead of mechanical agitators for some compartments, the mud guns should take suction from the same compartment into which they discharge. A centrifugal pump may stir this suction tank and should never pump fluid from one compartment to another.

7.3.9.3 The manufacturer’s guidelines shall be consulted for specific information on mechanical agitator blade size and geometry, and for power requirements.

7.3.10 Fluid Routing

7.3.10.1 Fluid is routed through process equipment downstream into the next compartment. The centrifugal pump used to power the jet on vacuum degassers shall take suction from the same compartment into which the vacuum degasser discharges.

7.3.10.2 The fluid shall be degassed before it reaches the pumps feeding downstream equipment.

7.3.10.3 Suction and discharge line diameter requirements depend upon the volumes of fluid to be circulated. Lines shall be sized in accordance with the manufacturer’s recommendations. See 7.8 and 7.9 for specifics.

7.3.10.4 Desanders shall draw suction from the compartment immediately downstream from the degasser compartment. Desilters and mud cleaners shall draw from the next compartment, and centrifuges from the next compartment.

7.3.10.5 Different types of equipment shall never take suction from the same compartment.

7.3.10.6 Like types of equipment shall always take suction from the same compartment.

7.3.10.7 The desilter portion of a combination mud cleaner shall be plumbed following the desilter guidelines, and the desander portion following those for desanders.

7.3.10.8 All solids removal equipment shall discharge processed fluid to the next downstream compartment.

7.3.10.9 Drilling fluid from other compartments shall never be pumped into a removal compartment from points downstream through mud guns, mixers, or the eductor of a vacuum degasser.

7.4 Design of Shale Shakers

7.4.1 Shale shaker skids shall be level.

7.4.2 Shakers shall be rigged with adequate space, walkways, and handrails to permit easy and safe servicing.

7.4.3 If the shaker is equipped with a rear tank (possum belly), the flow line shall enter the rear tank as near to the bottom as possible. To minimize the area where drill cuttings can accumulate, rear tanks that have the bottom of the tank at the height of the weir to the shaker screens minimize both cuttings accumulate and uneven flow to multiple units.

7.4.4 If the flow line enters the rear tank via an “elbow” over its top, the elbow shall extend to within one flow line diameter of the bottom of the tank.

7.4.5 A means of diverting fluid from the flow line is recommended to permit the disposal of cement, spotting fluids, contaminated fluids, etc. before these fluids reach the shale shaker. This procedure shall not be used to dump the rear tank into the sand trap before trips.

7.5 Operation of Shale Shakers

7.5.1 Inspect the screens every time circulation is interrupted.

7.5.2 Never bypass the shale shaker(s) while circulating or on trips into the hole. This includes dumping the rear tank into the active system.

7.5.3 Screen all fluids, including that shipped to the rig from elsewhere, before they enter the active system tanks.

7.5.4 Spray bars should be used only when required for the handling of gumbo or sticky clays. The orifices or jets on the bar shall be small enough to deliver water in a mist, rather than in a spray.

7.5.5 Use the shaker screens with the smallest openings that do not cause excessive drilling fluid loss. Some liquid loss through the discharge of wet solids off the shaker is often desirable for improving overall solids control efficiency and reducing the need for whole mud dilution as this discharge will contain more undesirable solids than an equivalent volume of whole mud.

7.5.6 Under normal operating conditions and when using a single-deck shaker with multiple screens, all screens shall have the same API designation (as defined in Section 11).

7.5.7 On double-deck shakers with flow in series through the two decks, the top screen shall always be coarser than the screen in the lower position. A difference of two API designation sizes is generally effective.

7.5.8 Replace or repair promptly all torn or damaged screens.

7.5.9 Do not routinely operate adjustable deck shakers in the maximum upwards position. This practice will cause degradation of cuttings, and on some shakers permit fluid to spill over the back of the screen bed.API RP 13C pdf download.API RP 13C:2014 pdf free download