API RP 585:2014 pdf free download.Pressure Equipment Integrity Incident Investigation

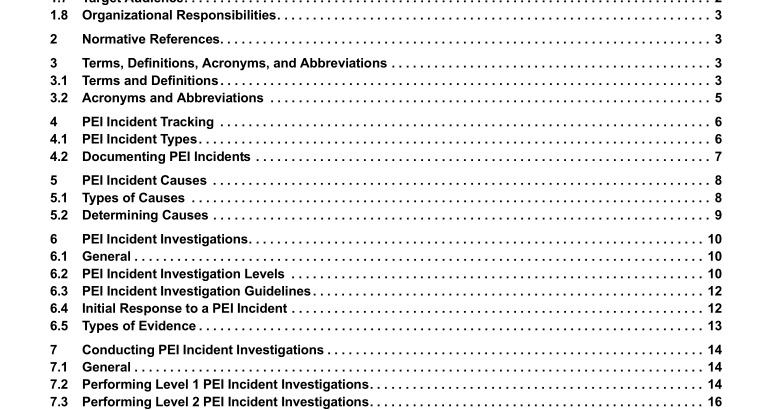

The purpose of this document is to provide owners/users with practices for developing, implementing, sustaining, and enhancing an investigation program for pressure equipment integrity (PEI) incidents. This recommended practice (RP) describes characteristics of how an effective investigation could be structured so organizations can learn from PEI incidents.

This RP is not intended to define or supplement criteria for compliance with regulatory requirements for which companies already have defined investigation processes in place. Rather, API 585 provides a specific focus on investigating PEI failures that are precursors to potential incidents that could have significant impact on safety, health, and environment. Significant mechanical integrity incidents are rarely the result of one isolated issue; there are almost always less severe precursors to a major failure.

These precursors are frequently called near misses when they are found. Additionally, this document highlights the value in recognizing these precursor occurrences and promotes investigating them to determine the immediate, contributing, and root causes. If these precursor occurrences are uncovered, investigated, and the contributing and root causes are resolved, then major catastrophic failures of pressure equipment could be minimized or prevented.

1.2 Industry Scope The investigation principles and concepts that are presented in this RP are specifically targeted for application to process pressure equipment in the refining and petrochemical industry but could be applied to other equipment at the discretion of the owner/user.

1.3 Flexibility in Application Because of the broad diversity in organizations’ size, culture, national, and/or local regulatory requirements, API 585 offers users the flexibility to apply the investigation methodology within the context of existing incident investigation practices and to accommodate unique local circumstances. API 585 is intended to promote the use of systematic investigations as a way to learn from unexpected leaks and equipment degradation or near misses associated with PEI. Investigation methodologies consist of investigators collecting evidence and conducting an analysis of the evidence to determine the causes. Many types of investigation analysis methods exist and are used throughout the industry.

This document is not intended to single out one specific analysis method for conducting investigations. This document highlights PEI issues for investigation and provides guidelines and work processes for PEI incident investigations.

1.4 Pressure Equipment Integrity (PEI)

Focused Investigation is a vital element for learning from unexpected discoveries or incidents (e.g. finding significantly more corrosion damage or other forms of deterioration than expected) and can be used in a continuous improvement process. Investigating and determining the causes of unexpected leaks, equipment degradation, or near misses associated with pressure equipment may be used to improve mechanical integrity programs and management systems for maintaining PEI, such as design and construction procedures, maintenance and inspection practices, and operating practices.

The Inspection, Corrosion/Materials, and Storage Tank Subcommittees of the API Committee on Refinery Equipment have produced a variety of codes and standards to guide owners/users in maintaining pressure equipment integrity and reliability, a listing is included in the Bibliography for reference.

1.5 Types of Pressure Equipment Covered

The following examples are the types of equipment considered to be within the scope of this document.

a) Pressure vessels—all pressure-containing components.

b) Piping—pipe and piping components (valves, expansion joints, sight glasses).

c) Storage tanks—atmospheric, low pressure, and pressurized.

d) Rotating equipment—pump and compressor cases and associated pressure-containing piping and pressure vessels, excluding seals.

e) Boilers and heaters—pressurized components.

f) Heat exchangers—shells, heads, channels, and pressure-containing components and tube bundles.

g) Pressure-relief devices.

h) Structural systems—integral to supporting pressure-containing systems.

i) Cooling water towers.

j) Stacks and flares.

Other types of pressure equipment can be included at the discretion of the owner/user.

1.6 Types of Equipment Excluded

The following nonpressurized equipment is not intended to be covered by this RP but could be included at the discretion of the owner/user.

a) Instrument and control systems.

b) Electrical systems.

c) Machinery components (except pump and compressor pressure-containing cases).

d) Structural equipment not associated with a pressure-containing component or system.API RP 585 pdf download.API RP 585:2014 pdf free download